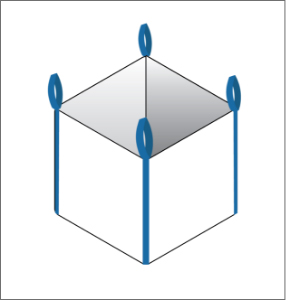

What is the Difference Between Coated and Uncoated FIBCs?

The main difference between coated and uncoated FIBCs is that the coated FIBC has an additional layer of protective coating on its fabric surface, while the uncoated FIBC does not.

Coated FIBCs are made by applying a layer of coating material, such as polypropylene or polyethylene, to the surface of the fabric. This coating can help to improve the strength and durability of the bag, as well as provide additional protection against moisture, dust, and other contaminants. Coated FIBCs are commonly used for transporting materials that require extra protection, such as chemicals or food products.

Uncoated FIBCs, on the other hand, are made from plain woven polypropylene fabric without any additional coating. These bags are generally less expensive than coated FIBCs and are commonly used for transporting materials that do not require extra protection, such as sand or gravel.

Overall, the choice between a coated and uncoated FIBC will depend on the specific needs of the material being transported, as well as the transportation and storage conditions. Factors such as moisture, dust, and the level of protection required will all influence the decision of whether to use a coated or uncoated FIBC.

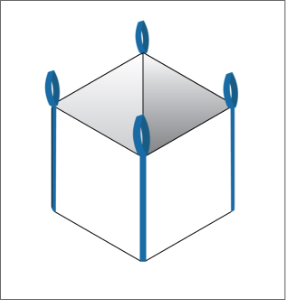

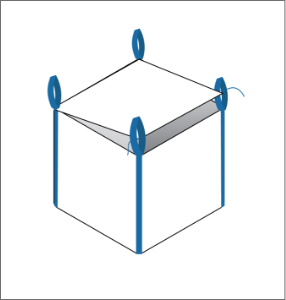

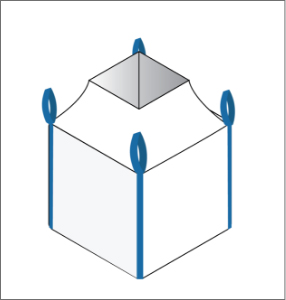

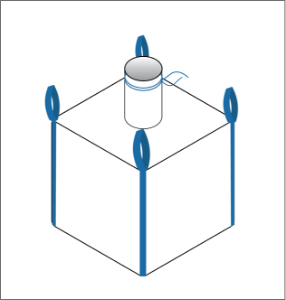

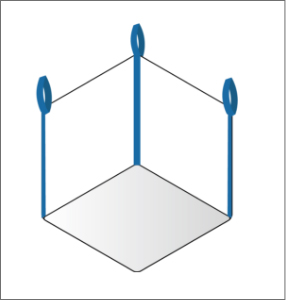

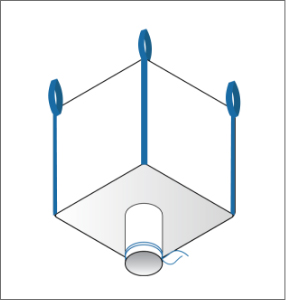

What is an FIBC Liner?

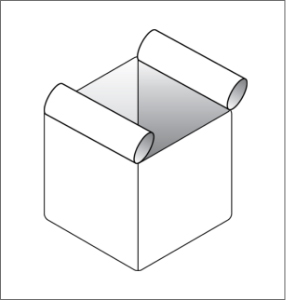

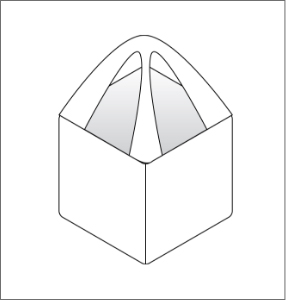

An FIBC liner is a removable, flexible, and often transparent bag that is placed inside a Flexible Intermediate Bulk Container (FIBC) to protect the contents from contamination or moisture and to prevent the contents from leaking out of the bag.

FIBC liners are commonly used in the transportation and storage of various materials, including food products, chemicals, and powders. They are made from a range of materials, including low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and polypropylene.

The liner is typically designed to fit snugly inside the FIBC and is suspended from the top of the bag using loops or tabs. Once the liner is filled with the contents, the top of the liner is typically folded over and secured, and the FIBC is then closed and secured using various mechanisms, such as a drawstring closure or a zip tie.

Lined bulk bags come with liners already built into the woven polypropylene. The advantage of FIBCs with liners installed is the many options you have. One disadvantage of lined FIBC bulk bags is that the liners are usually either sewn into the seams of the bag or tabbed to the bag’s material and cannot be removed. This makes it difficult to reuse when compared to using removable poly liners.

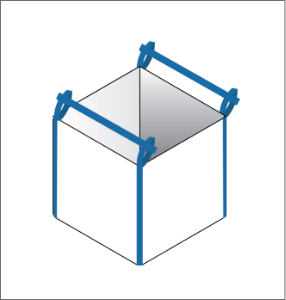

What is a Safe Working Load or SWL?

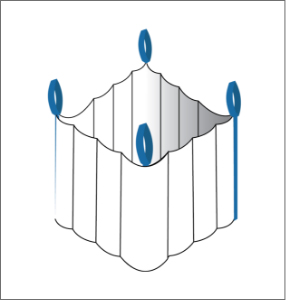

The safe working load (SWL) of an FIBC, or flexible intermediate bulk container, refers to the maximum weight that the bag is designed and tested to safely hold and transport. This weight limit is determined by the bag’s size, construction, and intended use.

The SWL of an FIBC is typically measured in kilograms or pounds and is indicated on the bag itself or on a label attached to the bag. The SWL considers factors such as the bag’s strength, weight, and stability, as well as any additional stress that may be placed on the bag during transport or handling.

It is important to note that the SWL is not a maximum weight limit for the bag itself, but rather the weight of the product that can be safely transported in the bag. It is also important to ensure that the bag is used in accordance with the manufacturer’s guidelines and that it is not overloaded, as this can compromise the bag’s integrity and lead to product loss or worker injury.

To ensure safe use of FIBCs, it is important to select the appropriate bag for the product being transported and to adhere to proper handling and transportation procedures. It is also recommended to perform regular inspections of the bags to ensure they are in good condition and to replace any bags that show signs of wear or damage.

Find the right FIBC for your business with Ovasco

Finding the right FIBC that perfectly suits your individual needs can be quite a daunting task, so here is some clarification on the basic types and variations to the FIBCs that Ovasco has to offer. Please do not hesitate to reach out to us for more information at sales@ovasco.com or give us a call at (502) 584-2219.